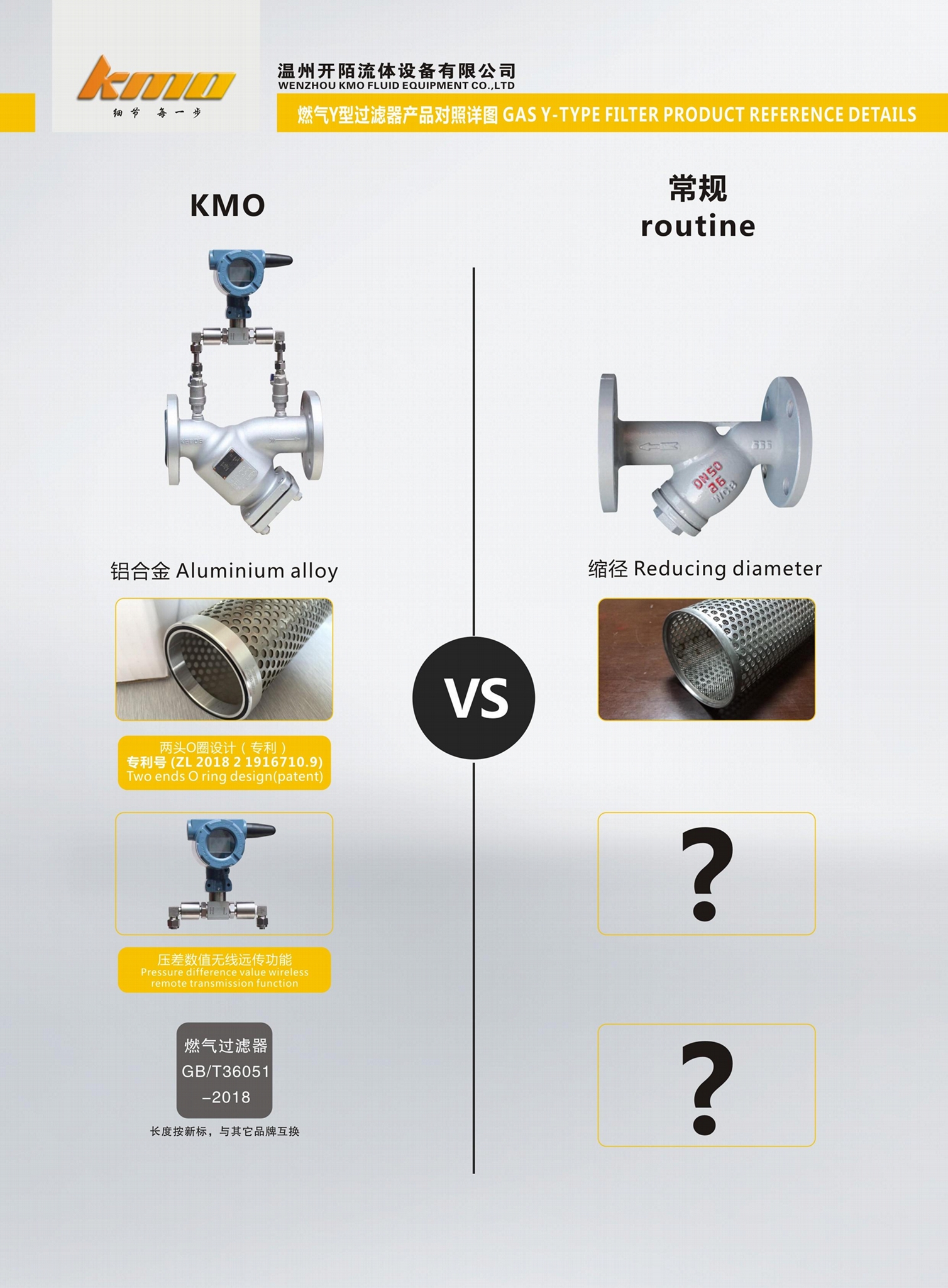

PN0.6MPa DN15 Remotely Controllable Aluminum Alloy Fuel Gas Y Type Strainers

Model No.︰KRYG1Y4F-6L

Brand Name︰KMO

Country of Origin︰China

Unit Price︰US $ 213 / pc

Minimum Order︰5 pc

Product Description

Product Introduction

The KRYG1Y4F strainer is an indispensable device in the pipe system that conveys gas and other media. It is generally installed at the inlet of gas equipment to remove the impurities in natural gas, liquefied petroleum gas and other media, protecting the valves, flow meters and pressure control devices, etc. KMO's strainer has advantages of advanced structure, low resistance and convenient sewage discharging. The applicable media includes liquefied gas and natural gas. According to user needs, the filter element is made of stainless steel with good firmness and durability. The meshes of the filter screen can be set according to user needs, generally selectable between 80~700 meshes. The connection ways include flange and screw. The strainer can be optionally equipped with a differential pressure gauge, which can remind the user when it needs to clean. The item has the small volume, fine filtering accuracy, convenient installation and maintenance.

- Body Material: aluminum alloy(more details please check the follow drawing)

- Applicable medium: gas

- Diameter: DN25-150mm

- Nominal Pressure: 0.6MPa

- Design temperature:-15ºC~ +60ºC

- Connection type: flange

- Filter meshes: 50 meshes or customer requirements

- Design Standard: GB/T36051-2018

- Structure&Length Standard: SH/T3411

- Flange Standard: GB /JB / HG / DIN

Features of Product

- Advanced structure, low resistance, and fast drainage.

- The pressure transmitter is powered battery. The gauge is wireless for output. And it can be controlled remotely by many kinds of communication equipment. It is suitable for remote and frequent detected area.

- LCD display. It can be sent according to the set pressure difference value or real-time pressure difference, which has the advantages of high sensitivity, high precision and high stability.

- It can be measured automatically and it is suitable for monitoring network systems of major gas companies.

- The open battery design is easy to replace at any time, and the applicable medium is liquefied gas and natural gas.

- The appearance of the filter screen is basically the same. The meshes can be made according to the user's requirements. The inner parts are made of stainless steel filtering cores according to the user's needs, making it strong and durable.

- The mesh number of the filter net can be set according to the user's needs, generally choose 80-700 mesh, the connection form has flange type and wire mouth type.

- An optional differential pressure gauge can be installed. When the pressure loss is increased due to the clogged filter screen, the filter element needs to be removed and washed or replaced.

- The product has small size, fine filtering accuracy, convenient installation and maintenance, low cost, and short sewage discharge time. It usually takes 5-10 minutes to install small models.

Notes for Use

- Keep the filter cavity clean before installation to prevent impurities from entering and affecting the use effect.

- When the strainer is tested for hydraulic strength, the intake valve should be closed firstly. After the test is completed, use 0.6MPA air pressure to conduct airtightness test on the strainer, differential pressure gauge and pressure guide tube. After the pressure is stabilized, opening the two intake valves slowly at the same time to avoid damage to the differential pressure gauge caused by excessive unilateral pressure

- According to the working conditions on site, it is recommended to periodically drain and clean the filter.

- KMO reminds the user that it is necessary to clean the filter element when the differential pressure gauge shows that the difference of the inlet and outlet pressure reaches 0.03MPA (or specified by the user). The cleaning step is that: ①cutting of the inlet and outlet valves of the filter to ensure that there is no pressure and medium in the inner cavity; ②taking out the detachable filter element and using a brush to gently remove impurities; ③reloading. If the cleanliness of the filter element still cannot meet the demand after cleaning, it is recommended to replace with a new filter element.

- After each cleaning, you need to re-test to ensure the tightness of the product, and replace the air in the filter with nitrogen.

- Closing the intake valve before venting, after the pressure is stable then slowly open the two intake valves at the same time , to avoid damage to the differential pressure gauge caused by excessive unilateral pressure.

Payment Terms︰ TT/TC

Product Image